Laser beam quality evaluation

Laser beam quality evaluation is the process of measuring and analyzing the characteristics of a laser beam to determine its suitability for a particular application. This process involves measuring various parameters of the beam, such as its power, spatial and temporal coherence, beam width, divergence, and shape. Evaluating the laser beam quality is essential for ensuring optimal performance, achieving desired outcomes, and reducing the risk of errors or defects.

Laser beam quality is a critical parameter that can significantly impact the performance of laser systems in a variety of applications, including industrial, medical, and scientific. In this article, we will explore the different methods for evaluating laser beam quality, including M² measurements, beam divergence, and beam propagation ratio, and explain the advantages and limitations of each approach. We will also discuss the factors that can affect laser beam quality, such as beam profile, wavelength, and mode structure, and their impact on laser performance. Additionally, we will examine the importance of proper alignment and calibration in achieving accurate measurements of laser beam quality.

In this article you will learn:

- How to assess laser beam quality?

- M² – definition and measurement

- Beam width parameters

- Beam Pointing in Laser Technology: Factors Affecting Accuracy and Stabilization Methods

- Understanding Jitter in Laser Beam Pointing: Causes and Impacts

- Understanding Coherence in Laser Beams

- Laser Power: Understanding and Monitoring Laser Energy Output

- Long term measurement of the laser beam parameters

How to assess laser beam quality?

- M² (beam quality factor): This is a dimensionless parameter that characterizes the beam quality of a laser in terms of the ratio of the actual beam waist to the diffraction-limited beam waist. A lower M² value indicates a higher beam quality.

- Beam width: This is a measure of the size of the laser beam at a particular point, such as the beam waist or the focus spot. A narrower beam width indicates a higher beam quality. See: Evaluation of the laser beam width

- Divergence: This is a measure of how much the beam spreads as it travels through space. A lower divergence indicates a higher beam quality.

- Strehl ratio: This is a parameter that compares the actual intensity distribution of a laser beam to the ideal intensity distribution. A higher Strehl ratio indicates a higher beam quality.

- Beam Profile: This is the measurement of the intensity distribution of a laser beam in a particular plane and it can be represented in many ways like the Gaussian fit or the Top-Hat fit.

- Wavefront: This is a way of representing how the wavefront of the laser beam diverges from a perfect wavefront. A wavefront sensor can be used for this measurement.

M² - definition and measurement

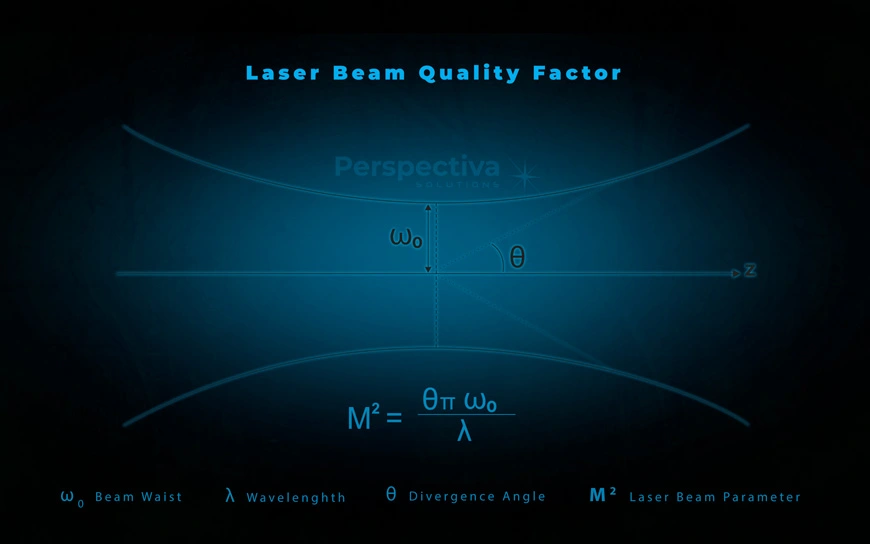

M² (pronounced “M squared”) is a dimensionless parameter that characterizes the beam quality of a laser. It is defined as the ratio of the actual beam waist (w0) to the diffraction-limited beam waist (w0,DL) at a particular point in space. The diffraction-limited beam waist is the smallest spot size that can be obtained with a perfect, diffraction-limited optical system, assuming a Gaussian beam at the same wavelength and divergent angle. A lower M² value indicates a higher beam quality.

When M² is equal to 1, then the beam is diffraction limited, it has smallest possible divergence and smallest achievable focal spot. Typically, real-life beams have M² in the range of 1.2-1.4. M² is never smaller than 1.

M² is commonly used to quantify the quality of laser beams, especially for high-power industrial lasers, and laser amplifiers, where the beam quality is crucial to the process or system performance.

It can be determined by measuring the beam size at different positions along the beam’s axis and then plotting these values as a function of position. A Gaussian fit can then be applied to these data to extract the beam waist and the divergence. By comparing these values with the values of an ideal Gaussian beam with the same wavelength and divergence, the M² can be calculated.

A common method to measure the M² is by using a beam profiler. A beam profiler is a device that captures an image of the beam profile and then analyzes the image to determine the beam’s characteristics. Here you can check examples of Huaris laser beam profilers.

Other methods include knife-edge scans and the use of beam diagnostic equipment like the far-field measurement.

It is worth noting that the M² is a single-valued parameter and it can be affected by the measurement position and the measurement conditions. It is also dependent on the wavelength and divergence. The higher the divergence of the beam, the lower the M² value.

Beam width parameters

Beam width is a measure of the size of a laser beam at a particular point, such as the beam waist or the focus spot. The beam width can be characterized by several different parameters, including:

Beam waist (w0): This is the point of the smallest spot size along the beam axis. The beam waist is often used as a measure of the overall quality of the beam and is commonly used to calculate the M² parameter.

1/e² radius: This is the radial distance from the center of the beam at which the intensity has dropped to 1/e² (about 13.5%) of the peak intensity. The 1/e² radius can be used as a measure of the width of the beam at a particular point and is commonly used to calculate the M² parameter.

Full-width-at-half-maximum (FWHM): This is the width of the beam at a point where the intensity is half the peak intensity. It is commonly used as a measure of the beam width for laser beams with Gaussian intensity distributions.

Beam diameter: This is a measure of the width of the laser beam at a particular point, and can be defined in many ways, such as the D4σ, D9σ, D15σ etc.

Especially, for the beam with irregular shape, a statistical approach is preferred. The most popular being: D4σ, or simply: 4σ.

It’s worth noting that different beam width parameters may be more appropriate for different types of lasers or applications. For example, the 1/e² radius is commonly used for laser beams with Gaussian intensity distributions, while the FWHM may be more appropriate for laser beams also with non-Gaussian intensity distributions. Additionally, a well-calibrated and well-designed system is needed to accurately measure these parameters.

The definition of most common beam width parameters (FWHM and 1/e2) is presented in the graph below:

Please mind, that beam width parameter is probably the most common metrics used to characterize the beam of a laser. For this reason it has been standardized and described in ISO 11146 norm.

In the mentioned standard the measurement of the elliptical beams has been also defined. The methodology of measuring such beams used in the Huaris software has been directly implemented according to this definition.

Beam width monitoring is a critical aspect to control the quality of the process conducted by the laser.

Beam Pointing in Laser Technology: Factors Affecting Accuracy and Stabilization Methods

Beam pointing refers to the ability of a laser to accurately point or direct its beam to a specific location or target. This is important in many applications, such as laser material processing, where the beam must be precisely focused on a specific location, or in laser communications or lidar, where the beam must be directed to a specific receiver.

There are several factors that can affect beam pointing, including:

- Thermal effects: As a laser is operated, it generates heat, which can cause the laser’s internal components to expand or move. This can affect the alignment of the beam and cause it to point in a different direction.

- Mechanical vibrations: Vibrations caused by external sources, such as equipment or the environment, can cause the laser’s internal components to move, which can affect the alignment of the beam and cause it to point in a different direction.

- Optical misalignment: The laser’s internal components, such as mirrors and lenses, may not be aligned correctly, which can cause the beam to point in a different direction.

- Power fluctuation: Power fluctuation can cause the beam to become distorted and not pointing accurately.

Turbulence: deviations of the beam spatial position due to the change of the change of density of gasses that the beam propagates through.

To maintain accurate beam pointing, a variety of active or passive stabilization methods can be used. For example, a laser’s internal components can be actively cooled or temperature-controlled to reduce the effects of thermal expansion. Mechanical vibration isolation can be used to reduce the effects of external vibrations. And feedback control mechanisms can be used to monitor and adjust the laser’s internal components to ensure that the beam is pointing in the correct direction.

Additionally, the beam pointing can be measured by using beam profilers or quadrant detectors, which can detect a small shift in the beam position, and use the information to adjust the alignment accordingly.

Typically the profilers can offer higher accuracies of the measurements of the beam pointing stability. The animation below presents how the position of the beam is monitored in the Huaris local application.

Understanding Jitter in Laser Beam Pointing: Causes and Impacts

Jitter refers to small, rapid fluctuations in a signal or a system’s performance. In the context of laser beam pointing, jitter refers to small, rapid fluctuations in the position of the laser beam. These fluctuations can be caused by a variety of factors, such as mechanical vibrations, temperature changes, or power fluctuations.

Jitter can be characterized by several parameters:

- RMS jitter: This is the root mean square (RMS) value of the jitter and it is a measure of the overall magnitude of the jitter.

- Pk-Pk jitter: This is the difference between the highest and lowest points of the jitter. It is a measure of the amplitude of the jitter

Temporal (or timing) jitter: This is the variation in the position of the beam over time. Essentially it refers to the situation, where each subsequent pulse should appear every specified period of time. However, in reality the consecutive pulses arrive sooner or later than expected. These deviations from expected arrival moments are called the timing jitter.

Jitter can be detrimental to many laser applications, particularly those that require precise beam pointing or alignment. For example, in laser material processing, jitter can cause the beam to move away from the intended target, leading to poor quality or incomplete processing. In laser communication or LIDAR, jitter can lead to poor signal quality, reducing the accuracy of the system.

To reduce jitter, the system must be designed with stability and mechanical vibration isolation in mind. Additionally, active or passive stabilization methods can be used to monitor and correct for jitter in real-time, for example, by using a feedback loop that adjusts the laser’s internal components to maintain accurate beam pointing.

Understanding coherence in Laser Beams

Coherence is a fundamental property of laser beams that refers to the correlation between different parts of the light wave. There are two types of coherence: temporal coherence and spatial coherence.

Temporal coherence:

refers to the correlation of the phase and frequency of the light wave at different points in time. A laser beam is said to be temporally coherent if the phase and frequency of the light wave is the same for all points in the beam over time. The temporal coherence of a laser can be described by the coherence time, which is the length of time over which the phase and frequency of the light wave remains constant. High temporal coherence is important in applications such as interferometry, where the phase and frequency of the light wave must remain constant over time in order to generate accurate measurements.

Spatial coherence:

refers to the correlation of the phase and frequency of the light wave at different points in space. A laser beam is said to be spatially coherent if the phase and frequency of the light wave is the same for all points in the beam. The spatial coherence of a laser can be described by the coherence length, which is the distance over which the phase and frequency of the light wave remains constant. High spatial coherence is important in applications such as laser material processing, where the laser beam must be focused to a very small spot, and maintain that focus over a long distance.

Within the spatial coherence the longitudinal and transversal spatial coherence is distinguished to stress direction in space over which the coherence is analyzed.

The coherence length (Lc)

is a measure of the degree of spatial coherence of a laser beam, it can be defined as the distance over which the light waves’ phase difference is less than 1 radian. It is a measure of the distance at which the phase of the light wave becomes random. It is a key parameter in many laser applications such as interferometry, holography and laser material processing.

It is worth noting that the coherence length and coherence time are inversely proportional to the spectral bandwidth of the laser, the narrower the bandwidth the longer the coherence length and time.

Typically, the coherence is measured using various kinds of interferometers.

Laser Power: Understanding and Monitoring Laser Energy Output

Power is a measure of the rate at which energy is transferred, and it is a fundamental physical quantity. In the context of lasers, power refers to the amount of energy per unit time that a laser can emit. The power output of a laser is typically measured in watts (W), milliwatts (mW), or microwatts (μW).

The power output of a laser is determined by the amount of electrical power that is supplied to the laser, as well as the efficiency of the laser’s optical system. The power output can be adjusted by adjusting the amount of electrical power that is supplied to the laser, or by adjusting the optical components of the laser’s system.

The power of a laser is one of its key parameters, as it affects the performance of the laser in various applications. For example, in laser material processing, a higher power laser can cut or weld thicker materials than a lower power laser, and in laser communication, a higher power laser can transmit a signal over a greater distance than a lower power laser.

It is also worth noting that the power distribution within the laser beam can also affect the performance of the laser, for example, a Gaussian power distribution is usually preferred for laser material processing as it provides a more symmetric and consistent heating of the material, while a top-hat power distribution is preferred for some optical micromachining processes as it provides a uniform and high intensity over a certain area.

It is important to know that Huaris Cloud allows long term monitoring of the laser power.

Long term measurement of the laser beam parameters

Measuring laser beam parameters, such as power, beam width, and pointing, over a long period of time can help to ensure that the laser is operating within its desired specifications and to detect and correct any changes or variations that may occur.

There are several methods that can be used for long-term measurement of laser beam parameters:

- Continuous monitoring: Using laser beam diagnostic equipment, such as beam profilers, that can continuously measure the beam parameters in real-time. This allows for the detection of any variations or changes as they occur, and immediate correction or adjustment can be made.

- Data logging: This approach consistsconsist of in capturing the laser beam parameters at fixed intervals using a beam diagnostic equipment, which are then logged and analyzed to identify any trends or changes that may occur over time.

- Comparison to a reference beam: This method incorporates consist in comparing the beam parameters of the laser under test to a known reference beam. This can be done by using a beam splitter and a reference beam profiler.

Environmental monitoring: This approach employs consist in monitoring the environmental conditions that can affect the beam parameters, such as temperature, humidity, and vibrations. This data can be used to identify any correlation with variations in the beam parameters.

It’s important to note that long-term measurement of laser beam parameters requires a stable and well-calibrated system. The measurements must be conducted under controlled conditions, to avoid any environmental or external effects that can affect the results. Additionally, it’s recommended to use a combination of methods, as each one can provide specific information or can help to cross-validate the results.

Huaris Cloud is a first in the world, commercially available system allowing long-term monitoring of the laser beam parameters. It does not only store the data, render and analyze using AI. It also detects time trends in the monitored parameters and warns the laser user about its occurrence suggesting that some preventive maintenance action should be taken. Read more about it.

Useful Huaris Links

Recent posts about laser beam profiler

Author